It is crucial to define:

- RIBA stages

- How Fire Safety corresponds with all of the stages

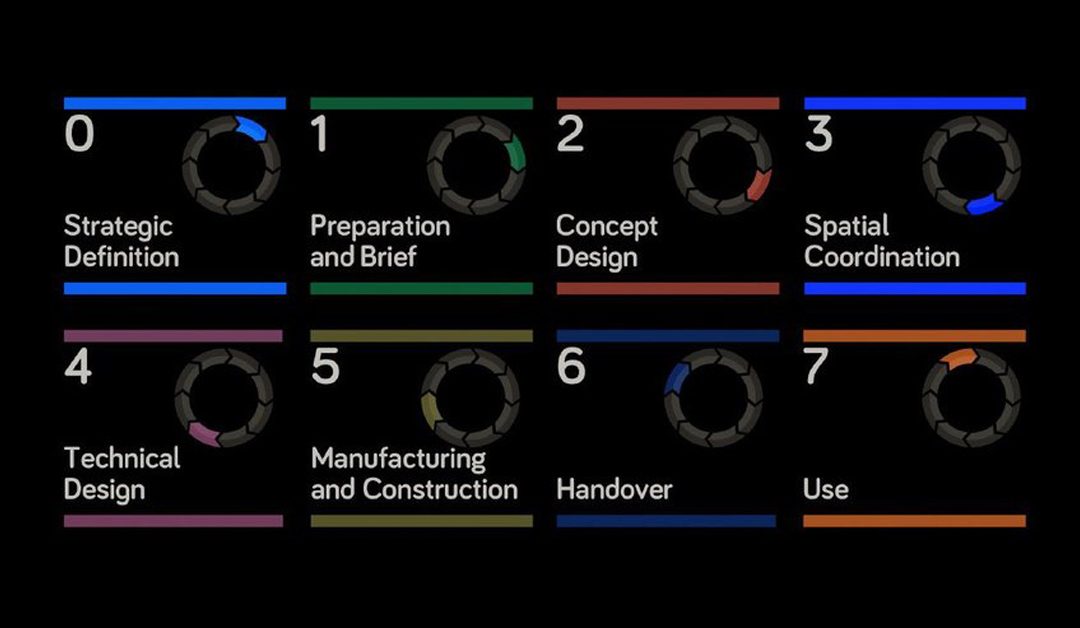

- What is RIBA and what are RIBA stages/plan of work?

RIBA is an industry-standard planning method that details each step of the process in a building, construction or design project. RIBA stands for the Royal Institute of British Architects, the global professional membership body for architects in the UK and around the world who publish the RIBA Plan of work.

There are 8 stages in the RIBA Plan of Work, numbered from 0 to 7.

- 0: Strategic Definition: During Stage 0, the project must be strategically appraised and defined, so that a detailed brief can be drafted. This is done to ensure that the client’s business case has been properly considered and addressed.

- 1: Preparation and Briefing: Stage 1 involves developing the project brief and conducting any necessary feasibility studies. Factors like site information, spatial requirements, budget restrictions, risk analysis and project outcomes must all be considered.

- 2: Concept Design: The initial concept design for the building will now be produced in line with the project brief. At Stage 2, the team will also develop several key project strategies, like security and sustainability.

- 3: Spatial Coordination: The concept design will be further developed, and the architectural, building services and structural engineering designs are coordinated and checked by the lead designer.

- 4: Technical Design: Stage 4 involves refining the architectural, building services and structural engineering designs in greater detail. Technical designs will be developed. Designs by any specialist subcontractors will be completed.

- 5: Manufacturing & Construction: This stage is when the actual process of building starts. This includes manufacturing building systems and erecting any components of the building that have been made off-site. During Stage 5, the designer should also carry out site inspections and compile quality reports.

- 6: Handover and Close Out: This phase focuses on the successful handover of the completed building, in line with the project programme and also includes completing initial aftercare tasks.

- 7: In Use: This involves a post-occupancy evaluation of the building to determine the project’s performance. It is also when facilities and asset management is implemented.

How Fire Safety Corresponds with all of the Stages

Fire Engineering

Fire Safety Engineer should ideally get involved in Pre-RIBA stages. The involvement of Fire Engineer in every RIBA stage is explained in the illustration above and in more details below:

- 0: In this stage, the general principles for the building are to be defined and discussed according to the building size and type.

- 1: Fire Engineer is to define current non-compliances and issues that might arise. The output of this stage would be a mark-up containing the guidance that will be used for the project. This outlined guidance is to propose recommendations for compliance. This mark-up would also normally describe any possible issue that might arise, depending on the type and size of the project.

- 2: Stage 2 is for identifying and evaluating the project’s specific requirements, constraints, and their influence on the Fire Strategy. Fire Engineer is to prepare and define Fire Safety requirements for the project. The product of this stage can be a mark-up or production of the Stage 2 Fire Strategy.

- 3: Fire Engineer is to undertake design studies, engineering analysis, and fire requirements in detail. In this stage, any areas that are not compliant are to be defined and to introduce alternative solutions, if necessary. These are all to be discussed with the design team and Authority Having Jurisdiction (AHJ). The outcome of this stage is the production of the Stage 3 report.

- 4: The Stage 4 report is to have all fire-related technical details, such as structural details, façade details, any additional analysis such as simulations, calculations, etc. Before the Stage 4 report is finalized, normally at least 2 site visits are expected to occur. The timing of these site visits will depend on the project complexity, organization etc.

- 5: During this manufacturing and construction stage, some issues typically arise, due to the buildability changes or new unplanned discoveries on site. Fire Safety Engineer will normally attend one more site visit and update the Fire Strategy Report (Stage 5 Fire Strategy).

- 6/7: This is the final issue of the Fire Strategy Report before handover, and it is to capture any last-minute and final changes. Production of the Stage 6/7 report is the outcome of this stage.

Throughout the stages, coordination between all disciplines is a must, in order to provide the best, well-rounded project at the end.

Fire Protection

The time of Fire Protection Engineer involvement can vary – the involvement could start in early stages, however, Fire Engineer involvement would normally go ahead first, followed by the involvement of a Fire Protection Engineer after the fire safety and systems requirements has been set by a Fire Engineer. Involvement in every stage is explained in more detail below:

- 0: Only involved if the Client advises that property protection with an active fire suppression system is required or if the building will obviously require fire suppression systems in the design (e.g. high rises, large storage warehouses etc). In this stage, Fire Protection Engineer is consulting and analysing the scope of the Project with the Architect and the Design Team.

- 1: Only involved if the Client advises that property protection with an active fire suppression system is required or if the building will obviously require fire suppression systems in the design (e.g. high rises, large storage warehouses etc). In Stage 1, Fire Protection Engineer is to identify and evaluate the specific requirements of the Project, the constraints, and their influence on the fire systems proposals.

- 2: Only involved if the Client advises that property protection with an active fire suppression system is required or if the building will obviously require fire suppression systems in the design (e.g. high rises, large storage warehouses etc). Stage 2 is for establishing and agreeing any additional requirements for the fire services equipment, particularly advanced installation and early use during construction. The output from this stage will be a concise Stage 2 Fire Systems Report containing high-level advise regarding the size of the systems required and their locations.

- 3: Normally, Fire Protection Engineer would get involved in this stage, after the Fire Safety requirements has been set by the Fire Engineer in Stage 2. Fire Protection Engineer normally provides schematic design studies including equipment requirements, performance criteria, and prepare and submit generic design information for the agreed design proposal, sufficient for incorporation into the architectural layout drawings.

- 4: In Stage 4, a detailed and complete performance-based specification is provided. The specification should include specific performance criteria, highlighting unique requirements of the Project, ensuring compliance with current codes and establish the equipment quality level. Tender documents are also normally configured to encourage competitive tendering.

- 5: This stage is for reviewing submittals from relevant Trade Contractor and subcontractors and as-built information for inclusion in O&M manuals. Furthermore, the Fire Protection Engineer co-ordinate Client’s and insurance inspector’s comments on the trade contractor’s submittals and to attend two site visits for the purposes of function testing and general dimensional check of the fire systems equipment and layout, including checking compliance of products with the specification. The output from this Stage is a set of drawings and technical submissions approved to at least Status B, or equivalent that will allow the trade contractor to release the design for manufacture.

- 6/7: The main focus of this stage is to review on key milestones and any identified risks to assist in planning and meeting a realistic programme. Fire Protection Engineer is to review and provide comments on the trade contractor’s project-specific method statements, risk assessments, process documentation and other suites of tools. Normally, two non-intrusive site visits are carried out in this stage, for purposes of reviewing the equipment, evaluation compliance of equipment and performance with contract document requirements, as well as for witness testing of the access equipment with the trade Contractor where appropriate.